Backshell Torque Tooling

Backshells on connectors are often used to provide strain relief and to protect the cable and connectors from environmental factors. For maximum reliability, the connector manufacturers provide a specific torque that the backshell should be tightened to. There are several ways that the amount of torque applied could be measured. Some will place the connector into a fixture with a calibrated torque wrench, with a fixed torque setting specific to the backshell being installed. Others will use a torque gauge and just stop tightening when the torque reaches the appropriate value.

At some point a need arose to be able to log the exact amount of torque applied to each backshell, and to eliminate some of the human error associated with logging that the backshell had been torqued and manually selecting the correct torque value to use.

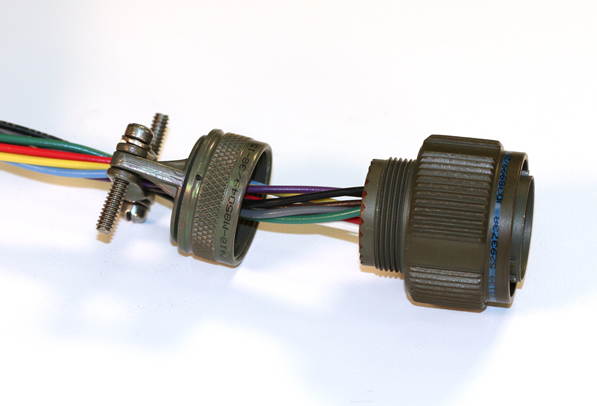

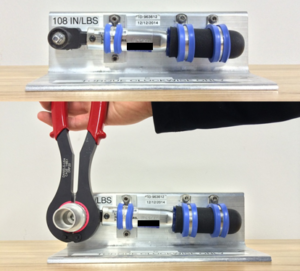

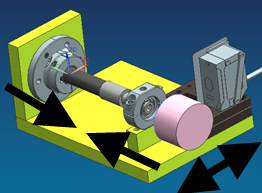

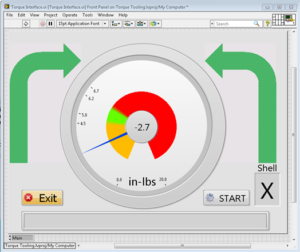

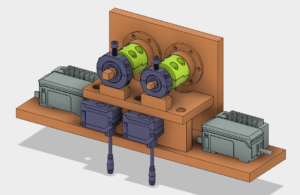

The first prototype used a computer to connect to a torque sensor, which could be coupled to a 38999 connector. One thing to note was that the torque required to apply to the backshell was directly related to the shell size of the connector. If you are unfamiliar with the 38999, it is a circular connector and it comes in various sizes. In order to detect the size of the connector, a distance sensor was used. It was in a fixed position, relative to the center of any connector. So the shorter the distance detected the larger the connector was. Below are images of the first prototype that was developed, along with the software that was used to run it. I used LabView to display the torque being applied to the backshell and shell size of the connector.

This first prototype used a Windows PC to interface to the torque and distance sensors. However a more portable solution was desired. .

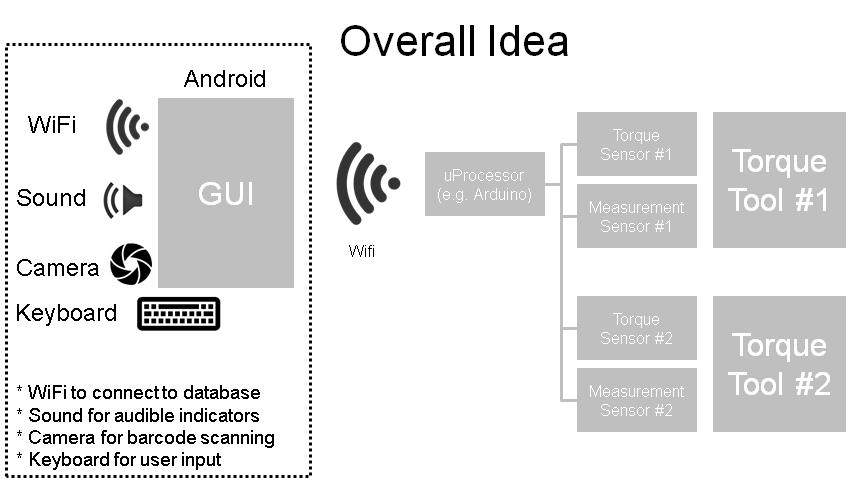

The next update involved using an Arduino board to read the torque and interface to the distance sensor. The distance sensors interface was RS-232, and the torque sensors generated an analog voltage. The Arduino would sample the torque and distance sensor data and output the information via wifi. You will note that there are two torque sensors on this prototype. The reason was that the smaller 38999 connectors had a different backshell adapter, than the larger connectors, and thus had to support both types. Unfortunately, I cannot find a picture of this working prototype with the Android tablet display.

Comments are disabled